- Predator cnc simulator full#

- Predator cnc simulator verification#

- Predator cnc simulator software#

- Predator cnc simulator code#

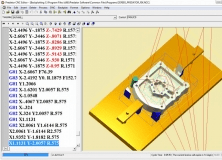

Independent CNC Verification and Validation CNC Verification Support includes milling, turning and mill/turn NCI and INC toolpaths. Predator Virtual CNC support's reading and writing of 2-5 Axis Mastercam NCI toolpath files and 2-5 Axis SURFCAM INC toolpath files. Learn more Mastercam and SURFCAM Toolpath Support Comprehensive 2-5 Axis APTCL support is included standard. Specific reverse posts for each of your CNC machines can also be purchased. Detailed online help with lots of examples document all of the CNC options available.

Predator cnc simulator code#

Predator Virtual CNC includes 150+ reverse posts to read a wide range of G & M code and conversational CNC formats from every major CNC machine builder to get you started. G & M Codes and APTCL Support via Configurable Reverse Post Processor Predator Dynamic Graphics™ provides realistic manufacturing simulation where: Predator Dynamic Graphics extend to measurement and inspection with 3D icons, dimensions, angles and points of measure. Predator Dynamic Graphics include automatic edge detection, automatic anti-aliasing, automatic hidden line removal, automatic texture mapping, automatic hidden surface removal and transparency. Visualization of plastics, metals, wood, stone, marble and rubber can be applied to stock, fixtures and machine components. Predator Dynamic Graphics supports 1600+ named colors, materials and textures.

Predator cnc simulator software#

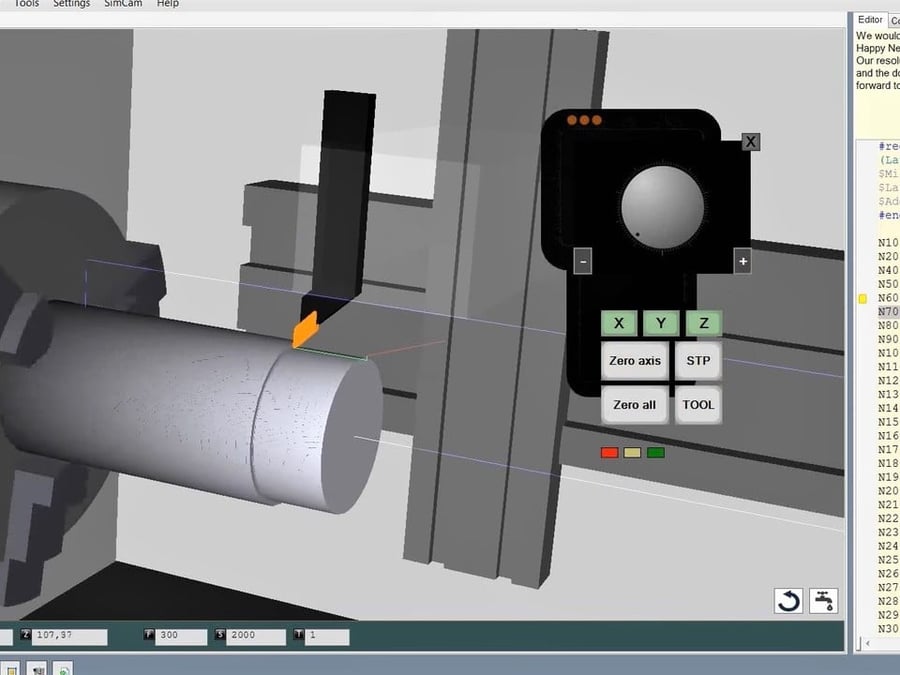

Predator Dynamic Graphics™ is a unique OpenGL based graphics engine developed by Predator Software to provide realistic CNC machining simulation and verification. Predator Dynamic Graphics™ - Realistic verification and simulation NOTE: Predator Virtual CNC™ does not support pinch turning, sub spindle transfers, parts catchers and swiss style turning. Standard lathe facing, turning, threading, grooving, roughing and drilling cycles are all supported. Live tooling support and barfeeder operation is simulated and supported. Parametric chucks and turrets simplify getting started and provide realistic simulation and collision detection. User definable machine tool configurations combined with our comprehensive library of reverse post processors allows standard HTLs and VTLs to be supported. Predator Virtual CNC™ supports 2, 3, 4 & 5 axis turning and complex Mill/Turn machines with live C and Y axis motion.

2, 3, 4 & 5 Axis Lathes and Mill/Turn Machines Support for rotary heads, rotary tables, nutated heads, nutated tables and multiple spindles are all supported.

Predator cnc simulator full#

Optionally define your entire machine for full collision detection of any moving part. Complex 4 and 5 Axis Machiningįull support for simultaneous 4 and 5 axis machining on mills and mill/turn machines. Complete 3+2 support is also available within Predator Virtual CNC 5 Axis. Processing speeds can be up to 3,000 blocks per second, while retaining the accuracy that you require. Predator Virtual CNC is optimized for 3-axis surface machining and can support huge files without running out of memory. Advanced cycles include subs, macros, variables, trig and logic codes are all supported. Standard milling, turning and drilling cycles are all supported. User definable machine tool configurations with our flexible reverse post processors allows standard VMCs and HMCs to be supported. Predator Virtual CNC™ supports all standard vertical, horizontal and complex machine configurations with 2 to 5 axis.

Predator Virtual CNC™ Software 3D Machine Simulation and Verification for 2-5 Axis Mills, Lathes, Mill/Turns, Lasers, Waterjets and Routers What is Predator Virtual CNC?

0 kommentar(er)

0 kommentar(er)